Cut Edge Corrosion

What is Cut Edge Corrosion?

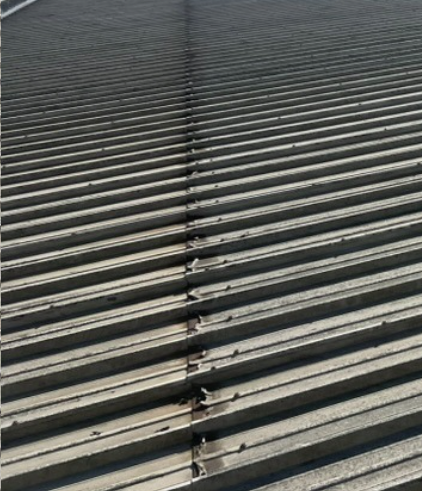

Cut edge corrosion occurs at the exposed edges of metal roofing/cladding where the sheets have been cut to size. cutting the panel exposes the protective coating and allows moisture and contaminants to penetrate, leading to rust and ultimately the deterioration at the edges. Over time, this can cause the metal to weaken, leading to structural issues and aesthetic problems.

Warranties

-

We are pleased to be approved applicators of many industry leading products and can therefore offer guarantees ranging up to 25 years. We work with various coating companies such as Rustoleum/ Tor coatings/ Giromax/ AkzoNobel / Lechler / HMG

We are pleased to be approved applicators of

Colour Matching

- Did you know We also offer a free site surveys and colour matching services.

Health & Safety

At Commercial Coating Solutions we take health and safety very seriously. Our technicians hold various licenses such as CSCS/IPAF/SSSTS/SMSTS/ PASMA. We are also proud to hold various accreditations such as CHAS and Safe Contractor. Prior to project commencement we will also provide a schedule of works, Method statement, Risk Assessment, and COSHH documentation.

- We are proud to offer our services nationwide 24/7

Benefits of Treating cUT eDGE coRROSION

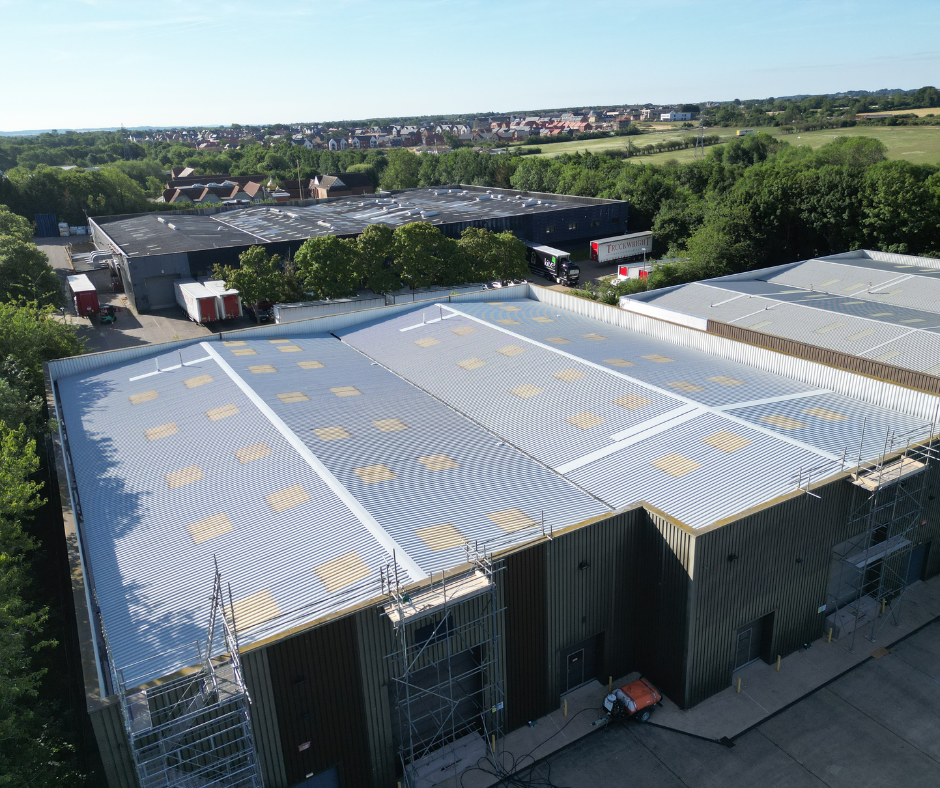

Latest Transformations

Our Process

Frequently Asked Questions

Cut edge corrosion occurs at the exposed edges of metal cladding where the protective coating is compromised. Treating it prevents further rusting, maintains structural integrity, and extends the life of your building’s exterior.

Our treatments come with warranties ranging from 5 to 25 years, depending on the products used, ensuring long-term protection and durability.

The process includes inspection, cleaning, surface preparation, applying anti-corrosion treatment, and finishing with a protective coating to prevent further damage.

Yes, we offer colour matching services to ensure the treated areas blend seamlessly with the existing cladding.

We plan our work to minimise disruption, offering flexible scheduling, including nights and weekends, to suit your business needs.

Signs include visible rust, peeling coatings, or water ingress at the edges of cladding. Contact us for an inspection to assess the severity and recommend the best solution.

Yes, it is a more affordable solution that prevents further damage and avoids the high costs associated with replacing entire panels or cladding.

Reach out to us for a consultation. We will inspect the site, discuss your needs, and provide a tailored plan for effective treatment and long-term protection.